🏺 The Art of Mug Design

The best mugs feel natural — balanced in weight, easy to hold, and visually aligned with your brand.

Our designers and engineers collaborate with clients to fine-tune every dimension:

-

Proportion & Balance: Ensuring ideal height-to-diameter ratios for visual harmony.

-

Grip Comfort: Ergonomic handle design for daily use.

-

Volume Accuracy: From espresso (6oz) to extra-large (20oz) formats.

-

Visual Consistency: Matching other tableware or brand collections.

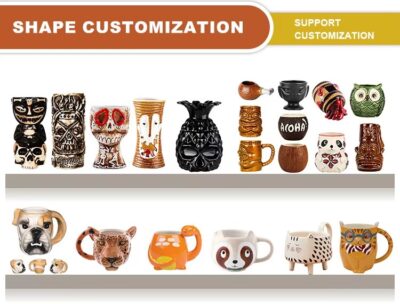

✏️ Shape Customization (OEM & ODM)

Whether you want a clean minimalist design or something artistic and sculptural, we offer full OEM mold development:

-

Classic Cylindrical: Timeless design for logo branding and café usage.

-

Tapered Forms: Slim at the bottom, wide at the top — elegant and contemporary.

-

Curved or Rounded Mugs: Soft silhouettes with comforting tactility.

-

Geometric or Novelty Shapes: For creative gift or promotional collections.

-

Double-Walled Design: Thermal insulation with a modern look.

Each shape starts as a 3D CAD model, then a plaster or resin prototype, and finally a custom mold for full production.

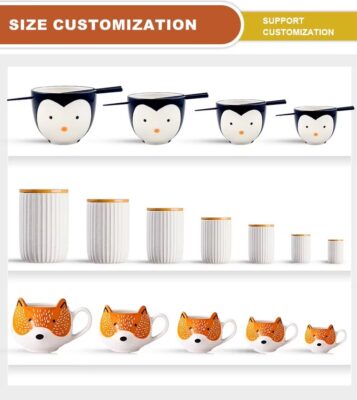

📏 Size Customization

Sometimes it’s not just about shape — it’s about proportion and purpose.

We customize mug sizes to suit different beverage cultures and product lines:

-

6oz–8oz: Espresso and tasting mugs.

-

11oz–13oz: Everyday home and office use.

-

15oz–17oz: Barista and branded retail mugs.

-

20oz and above: Promotional and oversized statement pieces.

We can adjust thickness, rim diameter, and handle span based on your preferred balance between durability and elegance.

🧱 Materials & Craft Techniques

Our ceramic mug factory combines modern precision with traditional expertise.

-

Porcelain: Lightweight, delicate, perfect for refined shapes.

-

Stoneware: Dense, solid, ideal for large mugs or rustic aesthetics.

-

High-Temperature Clay: 1250–1300°C firing for durability and heat resistance.

-

Advanced Molding: Slip-casting, pressure-casting, or semi-automatic forming depending on complexity.

Every curve, angle, and edge is polished by hand before glazing, ensuring a seamless touch and consistent thickness.

🎨 Design Integration

We can combine custom shapes with your logo, color, or surface finish for a unified brand design.

-

Embossed / Debossed Logo: 3D tactile branding directly into the mold.

-

Handle Branding: Logo or accent glaze applied on the handle side.

-

Interior Detailing: Glazed color or slogan printed inside the rim.

-

Set Coordination: Matching shapes across mug, saucer, and spoon for gift sets.

Each element contributes to a product that’s not only functional but emotionally resonant.

🧩 Packaging & Presentation

A mug’s journey doesn’t end at the kiln — it ends in your customer’s hands.

We offer custom-fit packaging for each unique mug shape:

-

Molded pulp trays or foam inserts for protection.

-

Printed gift boxes or minimalist kraft cartons for retail.

-

Optional barcode, hangtag, or brand story card integration.

Sustainability is built into our process — recyclable packaging and water-based inks available.

🔄 Customization Process

-

Concept Stage: Share your sketch, reference photo, or idea.

-

Design Stage: 3D model and structural evaluation by our engineers.

-

Prototype Sample: Handmade or cast for confirmation.

-

Glaze & Color Testing: Select surface finish and color combination.

-

Mass Production: 25–35 days after sample approval.

-

Quality Control & Shipping: Strict inspection and safe export packaging.

📦 MOQ & Lead Time

-

MOQ: 500 pieces per custom shape.

-

Sample Time: 10–15 days for mold and glaze testing.

-

Mass Production: 25–35 days after approval.

-

Logistics: Flexible shipping by air, sea, or express.

We also accept mixed orders with other product series to optimize your import process and shipping costs.

🌍 Why Choose Us

-

In-House Mold Workshop: From digital design to mold fabrication.

-

OEM/ODM Partner: Supporting design teams and brand owners.

-

Attention to Detail: Every handle, curve, and rim refined by skilled artisans.

-

Certified Quality: FDA/LFGB-approved materials, export-ready packaging.

-

Global Trust: Supplying cafés, retailers, and lifestyle brands worldwide.

With over a decade of experience, we’ve helped brands transform their design sketches into best-selling mugs across Asia, Europe, and North America.

FAQs

Q1: Can you make a completely new mug shape?

Yes, we provide full OEM mold development based on your 3D drawing or even a photo reference.

Q2: What’s the typical lead time for a new shape?

About 10–15 days for mold creation and sampling, and 25–35 days for mass production.

Q3: Do I need to pay for mold cost?

For exclusive designs, yes — mold fees are one-time and reusable for reorders.

Q4: Can I adjust existing sizes or handles?

Of course. We can slightly modify height, diameter, or handle style from existing molds.

✨ Final Thoughts

Shape defines emotion, and size defines purpose.

A well-designed mug feels natural, balances perfectly in hand, and reflects your brand’s style — quietly but confidently.

Partner with a dedicated custom shape and size ceramic mug manufacturer, and let’s create a mug that looks, feels, and sells exactly the way you imagine.