| Item | Detail |

|---|---|

| Capacity Options | 8oz / 10oz / 12oz / 14oz / 16oz |

| Dimensions (HxØ) | 8–10 cm × 7.5–9.0 cm (±2%) |

| Net Weight | 250–420 g per mug (by size) |

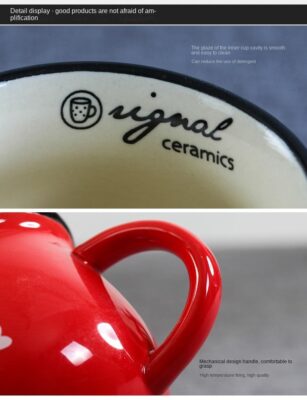

| Material Body | High-fired ceramic, enamel-style coating |

| Rim Options | Stainless rim / colored rim / plain |

| Finish | Gloss / matte / speckled enamel effect |

| Printing | Silk-screen, heat transfer, pad print |

| Full-Wrap Artwork | Yes (CMYK or spot colors) |

| Logo Area | Up to 220 × 60 mm (size-dependent) |

| Food Safety | LFGB / FDA-compliant inks & glaze |

| Use Cases | Cafés, hotels, retail sets, promotions |

| Packaging | Individual box / egg-crate / gift box |

| Customization | Colorway, handle shape, decal, sets |

Why brands choose enamel-style ceramic mugs

Ceramic enamel mugs combine the classic camp-mug look with the stability of high-fired ceramic. They’re sturdy, heat-retentive, and present a timeless silhouette that works across cafés, hotels, retail gift sets, and corporate programs. If you’re building a branded drinkware line, these mugs give you a proven canvas for impactful graphics without drifting into trend-only territory.

Built for everyday service

-

✅ Sturdy body: High-fired ceramic resists chipping and daily knocks in café or office settings.

-

☕ Heat retention: Thicker walls keep beverages warmer for longer, enhancing the drinking experience.

-

🧼 Easy care: Food-safe glazes and inks allow simple cleaning; standard prints withstand routine washing cycles (see care guide below).

-

🎨 Logo-ready surface: Smooth enamel-style finish delivers crisp lines and vibrant color blocks for both minimal and full-wrap designs.

Planning a product line centered on enamel-style looks? Explore our dedicated category for a broader range of capacities, rims, and finishes via Ceramic Enamel Mugs Manufacturers.

Printing & decoration options that scale

Whether you’re producing 500 mugs for an internal event or 20,000 for retail, our printing workflows scale cleanly from pilot to mass run.

-

Silk-screen — best for 1–3 spot colors, Pantone-matched; economical and sharp.

-

Heat-transfer decal — for complex art, gradients, or fine text; great color fidelity across large surfaces.

-

Pad print — precise small logos or secondary marks near the handle or base.

-

Inside-rim & bottom marks — add origin tags, batch codes, or subtle branding without cluttering the main artwork.

Artwork handoff: Acceptable file types include AI, PDF (outlined), or high-res PSD (300 dpi+). Provide Pantone references where color accuracy is critical. A pre-production digital proof comes standard; physical samples are available upon request.

Sizing, ergonomics & sets

Choose 8–10 oz for espresso-bar menus and corporate welcome kits; 12–14 oz for everyday café service; 16 oz for generous latte or iced beverages. Handle geometry can be standardized for cost efficiency or customized for premium lines. Retailers often pair a 12 oz enamel-style ceramic with a coordinated milk cup variant to create giftable 2- or 4-piece sets.

Compliance & durability

Our glazes and inks are formulated to meet common food-contact standards (LFGB/FDA). Standard prints are suitable for hand wash and light commercial dishwashing; heavy-duty dishwasher ratings can be achieved with upgraded inks and firing profiles. For long-term retail programs, we recommend a test batch in your target wash conditions to validate longevity claims.

Packaging that protects and sells

For wholesale and e-commerce, we offer protective egg-crate packing to minimize transit loss. Gift-box options (windowed or solid) can be branded to your style guide. Palletization follows ISTA-informed stacking and strapping to keep freight damage rates low.

Lead times & MOQs

-

Sampling: 5–10 working days after artwork confirmation.

-

Production: 20–35 days depending on print complexity and order size.

-

MOQ guidance: Standard colors from 500–1,000 pcs per design; split colors may be accommodated with combined total volumes.

-

QC: Incoming material checks, in-process inspections, and AQL-based final sampling before shipment.

For bespoke shapes, handle molds, or special rims, we advise locking specs early so we can align mold-making and decal preparation within your launch calendar.

Cost drivers to plan for

-

Number of print colors & coverage (spot vs. full-wrap)

-

Finish type (gloss vs. matte vs. speckled)

-

Rim detail (stainless ring adds a premium look and extra steps)

-

Packaging (plain bulk vs. custom gift box)

-

Compliance testing for specific markets if required

How to brief us effectively

Send: target capacity, finish preference, logo positions, Pantone codes, expected order volume, and packaging plan. If you run a multi-SKU program, share a 6–12-month forecast so we can stage materials and offer better pricing.

Looking to expand beyond enamel-style finishes? See our Custom Ceramic Mugs Manufacturers page for shape development, color-matching, and gift-set assembly services.

Care & Use (for your end customers)

-

Hand wash recommended for maximum print life; dishwasher-safe upgrades available.

-

Avoid metal scouring pads.

-

Microwave suitability depends on rim selection (metal rims are not microwave-safe).

What we emphasize in this offer

This page focuses on custom as the primary procurement term—clear, scalable customization from artwork to packaging—so buyers can move confidently from pilot to mass production without switching suppliers.

Optional Add-Ons

-

Bottom or inner-rim secondary logos

-

Serial codes or QR for campaign tracking

-

Matching milk cups in coordinated finishes

-

Retail display cartons and seasonal gift sleeves